Tim Shively, Wisconsin DNR Forest Health specialist for the West Central zone. / Photo Credit: Wisconsin DNR

By Wisconsin DNR

A list of public appearances planned by Wisconsin Department of Natural Resources (DNR) Forest Health specialists over the coming weeks:

- Tim Shively, DNR Forest Health specialist for the West Central zone, will present a forest health overview tailored for landowners, land managers and volunteers at a meeting of the Chippewa County Land Conservancy, set for 6:30 p.m. Tuesday, April 14, at Lafayette Town Hall, 5765 197th Street, Chippewa Falls

- Linda Williams, DNR Forest Health specialist for the Northeast zone, will present a forest health overview to loggers, truckers and foresters at the 21st annual Sustainable Forestry Conference, set for Wednesday, April 15, inside the ski lodge at the Keyes Park Recreation Area, 4960 County Hwy. 101, Florence. Registration is required. More event information can be found on the University of Wisconsin-Madison Extension website.

Linda Williams (left), DNR Forest Health specialist for the Northeast zone, addresses workers during a forestry seminar. / Photo Credit: Wisconsin DNR

The purpose of the

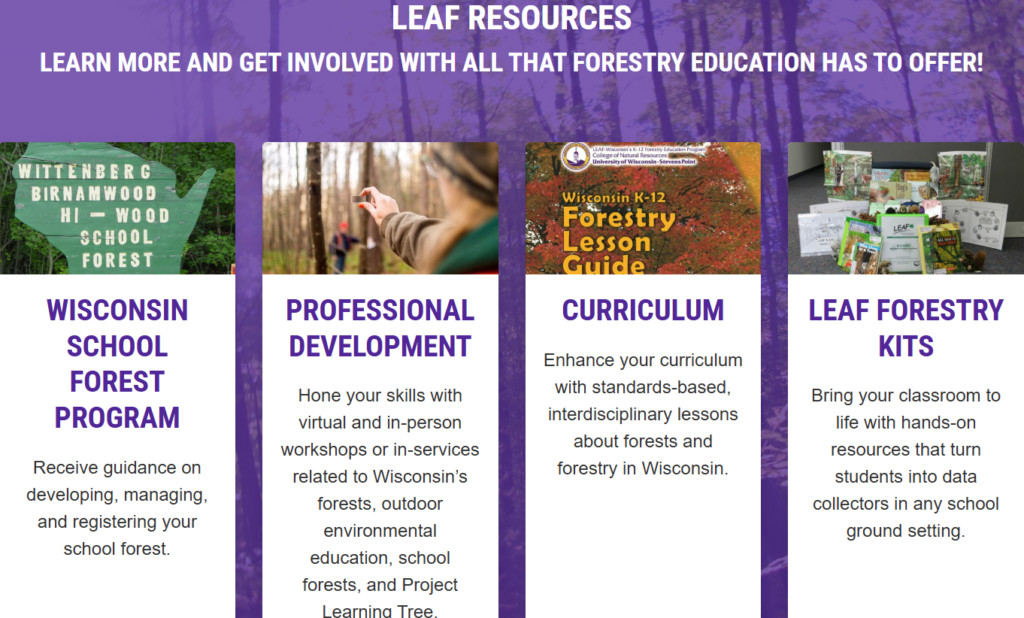

The purpose of the  Arbor Day is right around the corner, but why wait to start celebrating and learning about trees? The

Arbor Day is right around the corner, but why wait to start celebrating and learning about trees? The