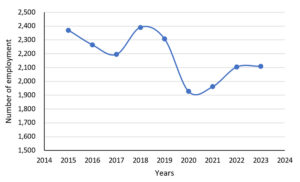

Housing Market Index (HMI) Survey, March 2025. Source: NAHB/Wells Fargo. / Graphic Credit: Brian Zweifel, Wisconsin DNR

By Brian Zweifel, DNR Forest Products Specialist, Dodgeville

Brian.Zweifel@wisconsin.gov

Variability and uncertainty seem like key words to describe many things right now, but the words apply especially to current housing markets.

The home construction and remodeling industry is a key driver of forest products markets and can be an important indicator of future demand. Softwood lumber and engineered wood products such as oriented strand board, plywood and laminated beams and joists are used in home construction. Hardwood lumber, however, is used to manufacture flooring, cabinets and other millwork items for interior applications.

Continue reading “Housing Wisconsin: Home Building Trends, Outlook”

With thousands of trees on their properties, municipalities and other urban ownerships sometimes need to remove a large volume of trees at once, such as after an insect or disease outbreak (i.e., emerald ash borer) or a catastrophic weather event (wind/tornadoes or ice/snow damage). When this need arises, what are the options available to remove these trees efficiently, safely, cost effectively and quickly?

With thousands of trees on their properties, municipalities and other urban ownerships sometimes need to remove a large volume of trees at once, such as after an insect or disease outbreak (i.e., emerald ash borer) or a catastrophic weather event (wind/tornadoes or ice/snow damage). When this need arises, what are the options available to remove these trees efficiently, safely, cost effectively and quickly?