Various panels of cross-laminated timber awaits a return trip to Madison, Wisconsin, for testing at the USDA Forest Products Laboratory. / Photo Credit: Wisconsin DNR

By Ram Dahal, DNR Forest Economist, Madison;

Ram.Dahal@wisconsin.gov

A recent study conducted by Michigan State University and the Wisconsin Department of Natural Resources highlights Wisconsin’s strong potentiality to locate mass timber industry in the state, leveraging its abundant forest resources, existing forest products infrastructure and growing market demand.

The study used logistics optimization model to evaluate feedstock zones, procurement costs, and transportation efficiencies, identifying two top potential locations in Wisconsin: near Stevens Point in Portage County and near Gull Lake in Washburn County.

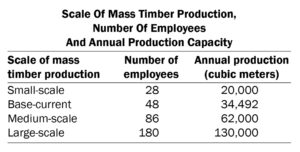

A chart showing the scale of mass timber production, along with the number of employees and annual production capacity.

The Portage County zone offers the best balance of feedstock supply and demand to urban centers, while Washburn County is the strongest candidate when focusing solely on timber and lumber supply. However, other factors such as workforce availability, infrastructure, community support, environmental consideration, and the specific socioeconomic or operational preferences of prospective investors may ultimately support different locations for siting a facility.

Analysis of historical softwood sawtimber availability using Forest Inventory and Analysis (FIA) data revealed significant feedstock availability for the identified optimal locations within the procurement zones, based on the current market delivered log price for softwoods. Washburn County has greater average annual softwood sawtimber availability than Portage County due to its proximity to forested areas. Among the Lake States, Wisconsin forests will primarily supply the feedstock, with some proportions from Michigan and Minnesota.

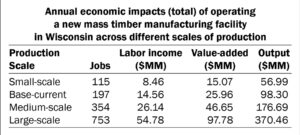

A chart showing the annual economic impacts (total) of operating a new mass timber manufacturing facility in Wisconsin across different scales of production.

The study found that a new facility could generate significant economic benefits. Depending on the size of the facility, small to large scale (Table 1), it could create between 115 and 750 jobs, generating $60 million to $370 million in output (Table 2) and producing up to $20 million in total tax revenue. In Washburn and Portage counties, total economic output could reach over $300 million. Washburn County, a more rural location, showed higher economic multipliers, indicating stronger localized benefits. Additionally, neighboring states would also benefit from increased trade and job creation.

Wisconsin’s forests, primarily privately owned, can supply most of the needed softwood, with supplemental supply from Michigan and Minnesota. The state also maintains strong inter-state trade in wood products, further supporting its readiness for mass timber production. In addition to economic gains, such a facility would promote sustainable forest management, revitalize rural communities, and enhance regional resilience in the forest products industry.