During National Forest Products Week, the USDA Forest Service announced it is making nearly $34 million in funding available through its Wood Innovations, Community Wood and Wood Products Infrastructure Assistance grant programs. The Forest Service is seeking proposals that support crucial links between resilient, healthy forests, strong rural economies and jobs in the forestry sector. Funding for these programs is intended to spark innovation, create new markets for wood products and renewable wood energy and expand processing capacity. You can read the full news release on the Forest Service’s website.

During National Forest Products Week, the USDA Forest Service announced it is making nearly $34 million in funding available through its Wood Innovations, Community Wood and Wood Products Infrastructure Assistance grant programs. The Forest Service is seeking proposals that support crucial links between resilient, healthy forests, strong rural economies and jobs in the forestry sector. Funding for these programs is intended to spark innovation, create new markets for wood products and renewable wood energy and expand processing capacity. You can read the full news release on the Forest Service’s website.

Forest Products News

Larry Krueger Shares Insights From Forest Products Industry Career

Photo credit: Larry Krueger.

The people who make Wisconsin’s forest products industry function are vast and varied. It’s estimated that more than 123,000 jobs in the state are tied to the forest industry. From the foresters and woodland owners caring for the forest to the loggers and truckers getting the logs from the forest to the sawmills and pulp mills throughout the state to the workers creating finished wood and paper products, it takes a wealth of passionate people to produce the many forest products you depend on every day.

Larry Krueger, a co-owner and sawmill manager of Krueger Lumber, is one of those working in the heart of Wisconsin’s forest products industry – fitting, as Krueger said he was born into it.

“My father Herb Krueger started Krueger Lumber in 1969,” Krueger continued. “The more you see the beautiful, natural products from our forest, the more you grow to love and appreciate its beauty.”

In his role, Krueger wears many hats. His day at the mill begins at 6:15 a.m. with a hard hat as he tours the sawmill to ensure smooth operations.

“I speak to various workers at different production points, checking for any problems and to see what’s new. I walk from the sawmill to the dry kilns and warehouses. I stop at the different lumber grading areas, speaking to the graders about any questions or issues they are seeing in the kiln-dried lumber being re-graded for quality,” he said.

Selling kiln-dried lumber is one of Krueger’s top priorities; after ensuring everything is running smoothly, he trades in his hard hat for a sales pitch.

“Throughout the rest of the day, I speak with and email regular and potential customers,” Krueger said. Continue reading “Larry Krueger Shares Insights From Forest Products Industry Career”

How Wisconsin’s Forests And Climate Initiatives Are Shaping A Sustainable Future

Wood stores carbon throughout its life. Photo credit: DNR

Wisconsin’s forests and forest products have a dual role in climate change. They are impacted by climate change, but also help mitigate its effects by storing carbon in wood products from sustainably harvested forests.

Sustainably managed forests in Wisconsin provide essential raw materials for more than 1,200 wood product companies and 280 logging businesses. Annual forest growth in the state significantly exceeds the volume harvested. In 2013, Wisconsin’s primary wood-using mills received 307 million cubic feet of industrial roundwood, while net growth reached 576 million cubic feet — an impressive 18 cubic feet of wood growing every second – and enough to fill Camp Randall Stadium roughly 108 times over.

When sustainably harvested wood is used in long-lived products such as lumber, furniture, windows and doors, it stores carbon throughout its life, only releasing it back into the atmosphere when it decays. Compared to concrete and steel, wood is gaining popularity as a building material due to its carbon-storing capacity – about half of dry wood is carbon – and its renewability. Additionally, it requires a less energy-intensive manufacturing process.

Continue reading “How Wisconsin’s Forests And Climate Initiatives Are Shaping A Sustainable Future”

The Economic Powerhouse Of Wisconsin’s Forest Products Industry

Wisconsin exported around $1.3 billion worth of forest products in 2022. Photo credit: DNR

The economic impact of Wisconsin’s forests cannot be understated.

The annual value of products from Wisconsin’s forest industry is over $24 billion, representing 2.3% of the state’s gross domestic product. Forest industries in Wisconsin employ around 58,000 individuals.

The economic influence of Wisconsin’s forest products industry extends to other sectors through inter-industry transactions and household spending. The forest products industry contributed an additional 66,000 jobs and $13.1 billion in output, bringing the total to over 123,000 jobs and $38 billion in production tied to the forest products sector. To help contextualize the scale of that impact, consider this: For every ten jobs in the forest products industry, 11 jobs were created in other areas of the economy.

Continue reading “The Economic Powerhouse Of Wisconsin’s Forest Products Industry”

The Everyday Impact Of Wisconsin’s Forest Products

It’s estimated 10 to 15 billion cubic feet of wood are used by Americans each year. Photo credit: DNR

Would you be able to name all the wood products you use daily? Paper is the most obvious, but wood products are all around you. From the insulation in your walls to the gum you chew after lunch, wood and forest products are almost everywhere you look, and many of them originate right here in Wisconsin.

Wisconsin’s primary forest products industry consists of firms that process logs and pulpwood into wood and paper products. Examples include sawmills, plywood mills, veneer plants, pulp mills, firewood processors and companies that manufacture log cabins, smoking pellets and other similar products.

Continue reading “The Everyday Impact Of Wisconsin’s Forest Products”

New DNR Forest Products Services Team Leader Named

Scott Lyon is the new leader of the Forest Products Services team.

The new year started with Scott Lyon taking over the helm of the Forest Products Services team. As the team leader, Scott will lead, direct and administer all policy, personnel and budget activities of the Forest Products Services Program. Scott will continue to work out of the Green Bay Service Center.

For the last nine years, he has worked as a forest products specialist with the DNR, helping industry partners improve processes, source wood products materials, utilize urban wood and providing training and assistance to companies and individuals. He previously worked in wood products sales and manufacturing domestically and internationally. Scott earned a bachelor’s degree in wood products business and marketing from Penn State and a master’s degree in forest products from Virginia Tech with an emphasis in international marketing. Scott recently completed the Leadership Academy training within the agency. As a result of his professional network, his connections span the geography of the U.S. and even reach internationally. In 2018, he was identified by the Woodworking Network on the “Woodworking Industry 40 Under 40” list as an innovator and relationship builder.

He currently serves on the Lake States Lumber Association as a board member of the Education Committee. He was also recently elected secretary of the Great Lakes Kiln Drying Association and secretary of the Northeast-Midwest State Foresters Alliance’s Forest Markets and Utilization Committee.

Scott lives in Green Bay with his wife and their new baby boy and their dogs. Scott’s hobbies include hunting, fishing, hiking, paddling and traveling to visit U.S. national parks and battlefields.

Previously, Collin Buntrock served as the program’s team leader. Collin left the DNR in August to join the U.S. Forest Service as a wood innovations specialist.

Where Are Wisconsin’s Forest Products Going? A Closer Look At International Trade

By Ram Dahal (ram.dahal@wisconsin.gov), DNR Forest Economist, Forest Product Services

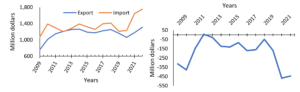

Wisconsin’s forest industry creates $24 billion of products each year. Historically, more than $1 billion of that total has included products sold internationally. However, did you know that in most years, Wisconsin imports forest products of an even greater value from international sellers?

Wisconsin’s international trade balance deficit exceeded $300 million in 2009, immediately following the Great Recession, but the deficit declined until 2012. In fact, Wisconsin had a trade surplus in 2012 but quickly resumed importing more forestry commodities than it was exporting (Fig. 1).

Figure 1: Wisconsin forest products foreign import export trend (left) and trade balance (right). / Source: U.S. Census Bureau

Continue reading “Where Are Wisconsin’s Forest Products Going? A Closer Look At International Trade”

Financial Support Available For Businesses Affected By Lack Of Snow

According to a press release from Gov. Tony Evers, many Wisconsin businesses might be eligible for a “federal disaster loan program” if they have suffered financial losses due to this winter’s unusually mild winter. The U.S. Small Business Administration has a list of counties attached to the press release where businesses are eligible to receive the financial relief. Learn more about the program.

Upcoming Forest Products Events

Great Lakes Kiln Drying Association Spring Meeting

Dubuque, Iowa

April 18-19, 2024

Learn more about this meeting.

Sustainable Forestry Conference

Keyes Peak Ski Hill Lodge

Florence, WI

April 17, 2024

Learn more about the conference.

Wisconsin Local-Use Dimension Lumber Grading

Kemp Natural Resources Research Station

Woodruff, WI

April 25, May 15 and May 16

Register for the training program.

International Wood Buyers Visit Wisconsin

By Scott Lyon, DNR Forest Products Specialist

From May 30 to June 2, 2023, eight wood buyers from Mexico, India, Thailand and Taiwan participated in an inbound trade mission that visited ten lumber manufacturers around the state. This event was hosted by the Wisconsin Department of Agriculture, Trade and Consumer Protection (DATCP) and New North, Inc., and was sponsored by the Wisconsin Initiative for Agricultural Exports and the Wisconsin Department of Natural Resources (DNR).

While visiting the Wisconsin manufacturers, the buyers learned about sustainable forest management practices, the wood species and types of forest products manufactured here in the state, and how the products could meet their existing market demand in their own country. In addition to visiting Wisconsin lumber manufacturers, the buyers were treated to a reception at the Menominee Casino in Keshena where additional lumber manufacturers from around the state were able to meet them and market their products. Menominee Tribal Enterprises was the host company during this event and provided the attendees with an overview of their tribal history, sawmill and forest management practices. Continue reading “International Wood Buyers Visit Wisconsin”